The big news (as of Friday) this weekend is that Sarah passed her orals, so she's now officially a PhD candidate. There was, um, some serious partying. I think I drank about 10 sangrias, and ended up trying to get from Pearl St. back to my house, very drunk, with 2 people (my pal Dave from the UK, who was, of course, also blitzed, and myself) on one bike. Shockingly, we made it, and didn't even crash, though I was pretty worried a few times when I was sitting on the saddle and Dave was "steering". We woke up at noon on Saturday and battled raging headaches, then tried to ride at Green Mountain this afternoon. Green Mountain is NOT dried out. We ended up walking through snowdrifts almost as much as we rode our bikes.

Put a new WTB Weirwolf 2.55 tire on Sarah's bike and she liked it pretty well. I was interested to notice that it's actually very slightly *smaller* than the Exiwolf, which is ostensibly a 2.3" tire, and made by the same company. Are the folks at WTB just totally incapable of measuring things, or do they not understand the metric system, or what? I mean, the tire is 56mm wide. That's about exactly 2.2". So, ok, call it a 2.3 if you want. Fine. But 2.55? First off, 2.5 doesn't make any sense, because, well, it's not that big. But _2.55_?!? That's hilarious not just because it's wrong, but because it's unbelievably precise in its wrongness - what the heck is the extra 5 for? Why not add a few more digits? I tell you, my 2.556 hooks up WAY better than that 2.553 I was running last year... I think the only way to make this kind of measurement more annoying would be to express them as fractions of prime numbers or something.

Best book this week: Perdido Street Station by China Mieville. Think Dickens meets Neil Stephenson meets Orson Scott Card. Wicked stuff, great writing and characterization and a fantastic and internally consistent universe. The story itself is the weakest aspect of the book, but it's good enough to let you enjoy everything else.

Sunday, February 25, 2007

Thursday, February 22, 2007

Sun, sun, sun.

We've had a couple of 50-60 degree days in a row, which means that riding a bike is possible again - and the streets are finally clear of snow. Apparently Denver just missed setting a record (for Denver, that is) for longest continuous snow coverage - the old record was 62 days, and we made it 61 this time. Not something I'm super psyched about, but still interesting. If I survive this winter, I think I can handle anything.

Here's the latest project (CAD work courtesy of the fine Mr. Feldman). Care to speculate what the heck this sucker is? Don't worry, there will be more info soon, as well as some blast-from-the-past type posts that will make you laugh.

Here's the latest project (CAD work courtesy of the fine Mr. Feldman). Care to speculate what the heck this sucker is? Don't worry, there will be more info soon, as well as some blast-from-the-past type posts that will make you laugh.

Wednesday, February 21, 2007

Waltworks spring cleaning.

Click here to check out the Waltworks spring cleaning/garage sale.

Lots of good stuff, some crappy stuff, and everything for really, really cheap. Help me clean out the shop, dudes and dudettes.

I got squat done yesterday, because it was 55 degrees and I decided to go riding instead of doing any work. Now it's 60 degrees and I'm stuck inside. Doh!

-Walt

Lots of good stuff, some crappy stuff, and everything for really, really cheap. Help me clean out the shop, dudes and dudettes.

I got squat done yesterday, because it was 55 degrees and I decided to go riding instead of doing any work. Now it's 60 degrees and I'm stuck inside. Doh!

-Walt

Monday, February 19, 2007

New weightweenie fork mods

Ok, I like to say that I don't care much about weight, but the reality is that if you own a gram scale (guilty, as charged) you're pretty much solidly in the weightweenie camp. Now, don't get me wrong - I have no interest in building *fragile* lightweight stuff, but getting rid of extraneous material is something I can dig.

In that spirit, I've been testing some new modifications (minor tweaks, really) to my fork designs to save a few more grams without giving up any strength. After some beta testing by yours truly and my "team"/guinea pig squad, I'm offering them to the general public.

First mod is pretty straightforward, but it took some work to make a fixture to hold onto the dropout to allow it to be machined down. See the pictures - I remove most of the plug portion of the dropout (since I weld these in, the plug isn't necessary - it's for those folks who want to braze the dropouts in with brass), which saves about 15g/pair, and then I cut/file away the rack mounts (which most folks don't want/need) as well, to save another 7g or so.

Before:

And after:

I've also found some fork blades that will allow me to use asymmetrical blades on disc forks - reinforced/beefy left legs that can handle the extra force of the disc, with new lighter weight right legs, since the brake forces aren't nearly as high on that side. This mod saves only a little weight on the constant diameter blade forks (usually 10-15grams) but it can save as much as 50g on tapering blade forks.

It takes a reasonable amount of extra work to do this, so I'm going to charge an extra $20 for the weightweenie mods.

Bottom line is that my lightest suspension corrected 29er forks will now run as light as 850 grams (final fork weight depends on the rider, of course, but the mods will save you 25-65 grams regardless) and I'll still offer my "lifetime unless you do something stupid" warranty.

In that spirit, I've been testing some new modifications (minor tweaks, really) to my fork designs to save a few more grams without giving up any strength. After some beta testing by yours truly and my "team"/guinea pig squad, I'm offering them to the general public.

First mod is pretty straightforward, but it took some work to make a fixture to hold onto the dropout to allow it to be machined down. See the pictures - I remove most of the plug portion of the dropout (since I weld these in, the plug isn't necessary - it's for those folks who want to braze the dropouts in with brass), which saves about 15g/pair, and then I cut/file away the rack mounts (which most folks don't want/need) as well, to save another 7g or so.

Before:

And after:

I've also found some fork blades that will allow me to use asymmetrical blades on disc forks - reinforced/beefy left legs that can handle the extra force of the disc, with new lighter weight right legs, since the brake forces aren't nearly as high on that side. This mod saves only a little weight on the constant diameter blade forks (usually 10-15grams) but it can save as much as 50g on tapering blade forks.

It takes a reasonable amount of extra work to do this, so I'm going to charge an extra $20 for the weightweenie mods.

Bottom line is that my lightest suspension corrected 29er forks will now run as light as 850 grams (final fork weight depends on the rider, of course, but the mods will save you 25-65 grams regardless) and I'll still offer my "lifetime unless you do something stupid" warranty.

Friday, February 16, 2007

D'oh! Ow!

Just for reference, if you are cutting a chainstay that has some nice jagged edges from slotting it on the mill, and your gloves are on the other side of the room, you should probably go get them, rather than being lazy and using the hacksaw with bare hands. Ouch ouch ouch. I think I pretty much lost the whole knuckle, but I glued the flap of skin back down (as you can see, I did a really nice job of it) so maybe it'll heal back on.

C'est la vie. No climbing gym for me this weekend. I can just imagine crimping down really hard on some hold and having blood start to spurt out of my finger.

Tuesday, February 13, 2007

Tubing

I use as much domestically sourced material and tubing for my frames as possible. In general, that means I use a lot of tubes from True Temper sports, primarily their OX Platinum and Verus HT lines. I also use plenty of 4130 cromoly for smaller bits, and bottom bracket shells and dropouts from Paragon machine works.

This does not mean that I will not use other tubes and dropouts if appropriate - I start from scratch with every design and use the tubes and parts that I feel will work best for each rider.

Got a question about tubes or frame parts? Drop me a line, I'll be happy to chat with you about it.

This does not mean that I will not use other tubes and dropouts if appropriate - I start from scratch with every design and use the tubes and parts that I feel will work best for each rider.

Got a question about tubes or frame parts? Drop me a line, I'll be happy to chat with you about it.

Monday, February 12, 2007

Delays, delays

I was going to post some neat pictures of Fuentes' Actiontec-suspended 29er this week, but it's waiting for some brakes (and some other stuff) and as such, it's still in pieces. He's pretty excited about it - mostly because he's a big weight weenie, and the XL-size frame/fork/headset are under 7.5 pounds. We'll see how well he likes having 60ish millimeters of travel after riding on a Reba all of last year, though.

So not much bike news to report. I've been doing a decent amount of reading - the Boulder public library will send you a book by mail for $1, which is a pretty sweet deal, but for a geek like me (I read probably a book a day in a good week) it starts to add up fast. But when the choice is a 30 minute bike ride across town, or a few clicks of the mouse, it's awfully hard to stop myself. I shudder to think how broke I'd be if I actually bought books.

Best couple of books I can recall in the last month, in the off chance anyone wants to read them, were The Anubis Gates, by Tim Powers, a biography of J Robert Oppenheimer called American Prometheus, and an annotated version of The Princess Bride (the story, of course, is by Morgenstern, but the abridgement/screenplay was written by William Goldman, who provides some nice notes about how he approached the slash-and-burn/edit process). I've also been reading the "Dresden Files" books by Jim Butcher, which are embarrassingly badly written (not that I could improve upon them, though) but pretty killer, story-wise. I hear there's a TV version of the series now on the SciFi channel, but since we don't have TV, I'll have to miss out on being disappointed by it.

Don't worry, the blog will keep on mostly being about bikes. I swear. Lots of pictures of stuff on the gram scale and rumors from inside "the industry", plus Walt's secret training tips, coming soon!

So not much bike news to report. I've been doing a decent amount of reading - the Boulder public library will send you a book by mail for $1, which is a pretty sweet deal, but for a geek like me (I read probably a book a day in a good week) it starts to add up fast. But when the choice is a 30 minute bike ride across town, or a few clicks of the mouse, it's awfully hard to stop myself. I shudder to think how broke I'd be if I actually bought books.

Best couple of books I can recall in the last month, in the off chance anyone wants to read them, were The Anubis Gates, by Tim Powers, a biography of J Robert Oppenheimer called American Prometheus, and an annotated version of The Princess Bride (the story, of course, is by Morgenstern, but the abridgement/screenplay was written by William Goldman, who provides some nice notes about how he approached the slash-and-burn/edit process). I've also been reading the "Dresden Files" books by Jim Butcher, which are embarrassingly badly written (not that I could improve upon them, though) but pretty killer, story-wise. I hear there's a TV version of the series now on the SciFi channel, but since we don't have TV, I'll have to miss out on being disappointed by it.

Don't worry, the blog will keep on mostly being about bikes. I swear. Lots of pictures of stuff on the gram scale and rumors from inside "the industry", plus Walt's secret training tips, coming soon!

Monday, February 05, 2007

Brian's S&S coupler 29er

Brian was interested in seeing some of the pictures of the process that goes into installing the S&S couplers, made by S and S machine (the S&S site is extremely confusing and appears to have been designed by someone moderately schizophrenic, but the couplers themselves are great).

In any case, I thought this was a good idea, because there are a lot of misperceptions about how these things work and how the frame is actually built. I do NOT build the frame and then cut it in half, folks!

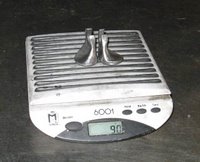

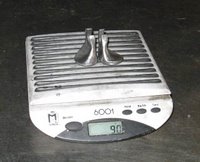

First, here's a picture of the hardware - as you can see, it's not light. The couplers (this is a set of pretty big ones for a large mountain bike) weigh in the neighborhood of 2/3 of a pound, though you also use about 1 ounce less frame tubing when building with them. So they aren't particularly a weight weenie accessory.

The first step is to figure out where the couplers need to go. This is surprisingly easy with anything but a truly tremendous bike - the couplers can go most anywhere on the top and down tubes near the seat tube, and the bike will fit into its case just fine. The trick is making sure that the coupler is in the butt (thick portion) of the tube - they aren't meant to be installed on the thinner center section. Once I figure all that out, I miter the rear/seat tube joint portion of the tube (the coupler itself won't clamp well into my mitering fixture, so it's necessary to miter before installing) and cut where I want the coupler. In many cases, I remove a significant portion of the butted section, because the coupler adds quite a bit of length to the tube (about 1 inch) and I need to make sure that I have enough butt at the head tube end.

Next, I clamp the tube in the workstand, cover it with flux, and install the coupler. Here's a picture of the fluxed-up setup. For this end, I don't have to be careful about the orientation of the coupler, because the tube has yet to be mitered.

Next, I braze the coupler in using 56% silver. This isn't the easiest operation, because the coupler is stainless steel, and it has some nasty thin bits that are easy to overheat and cook the flux (meaning that the silver won't flow where it needs to, and the joint won't be a strong as it should). I've done a lot of them, though, so it's not too stressful. This is the same process that is used when building a lugged bike. Here's a picture of the brazed joint.

Next, I braze the other side of the coupler to the short cut-off section of the tube. This time, I have to make sure the points of the lug on the coupler line up with the sides of the tube - I don't like putting points on the top or bottom of the tubes, because I'm a little uncomfortable with the points in the same plane as a lot of the major stresses that the frame will undergo.

Here's a picture of both parts of the coupler brazed into the tube.

Next, I have to get the flux off (it attracts moisture and will end up leading to a rusty tube if it's not cleaned off), so I soak the couplers and tubes in boiling water for 10 minutes or so. I'm not allowed to do this in the house, and I've kicked over the can enough times now that I won't do it in the shop either, so it gets done outside the garage. Yogurt containers are what the pros use, guys.

Finally, I clean off the remnants of the flux with a stainless steel brush. Note that I've done a little bit of polishing of the couplers here so that you can see what's going on, but I won't do a final polishing run on them until the frame is ready to take to the powdercoater. The couplers are stainless, so I like to have them masked so that the polished stainless shows up against the powdercoated tube with a nice defined point. Looks neato, and there's no corrosion concern. Of course, on a mountain bike, the coupler is generally just going to be covered up by a rubber sleeve anyway, but whatever.

Here's the final product, ready to be mitered up and welded into the frame. From here, it's pretty straightforward in terms of frame construction, so the photos and explanations will stop there. I will eventually do an exhaustive "how I build a frame" post or two, but it's not going to be today.

Finally, here are some general thoughts about S&S coupler bikes.

-You will not notice them when riding (unless you can notice the weight, I guess). The couplers are just as stiff as the tube section they replace, and if properly tightened, are undetectable in the ride of the bike.

-They're not cheap. The couplers are $350, and a good hard case is another $300 (I do not recommend the "designer" case that S&S sells). So you'll be $650 in the hole right off the bat. You'll save $50-75 each time you fly, though (usually each way) so you can make that money back in 3 or 4 trips.

-They are a pain to pack. You need practice in packing them, and even with some experience, it will take between 20 minutes (for a road bike) and 45 minutes (for a large 29" mountain bike) to pack the bike. Figure half that time to unpack and reassemble. So they aren't good for extremely short trips - you'll spend more time packing and unpacking than riding if you're just going for a day or two. Sarah and I use ours only for trips that are at least 3 or 4 days long. For shorter trips, we'll just rent bikes or go running instead.

-If not packed *perfectly* they'll get dinged up on the plane because the parts shift around inside. You can pack with lots of foam tubes on the frame and put all your small parts in a clear river-running drybag to keep this from happening, but it will add to the packing and unpacking time. Keep in mind that TSA will often open/rummage through the case, and that they may not be as careful as you are when closing it back up. If scratches or chipped paint upset you, this could be a bad thing.

-Extremely large mountain bikes (over 26" toptube) often will not fit in the 10" (airline kosher) case. I have seldom had my case measured, but if it does happen, you could end up paying the regular bike fee.

-The case+complete large mountain bike weighs about 45 pounds. In most cases, the weight limit for a single item of luggage is 50 pounds, so there's no way to pack lots of other stuff in with the bike without going over.

In summary, S&S couplers rule if you like to travel with your bike, and you have the patience to learn to pack it correctly.

In any case, I thought this was a good idea, because there are a lot of misperceptions about how these things work and how the frame is actually built. I do NOT build the frame and then cut it in half, folks!

First, here's a picture of the hardware - as you can see, it's not light. The couplers (this is a set of pretty big ones for a large mountain bike) weigh in the neighborhood of 2/3 of a pound, though you also use about 1 ounce less frame tubing when building with them. So they aren't particularly a weight weenie accessory.

The first step is to figure out where the couplers need to go. This is surprisingly easy with anything but a truly tremendous bike - the couplers can go most anywhere on the top and down tubes near the seat tube, and the bike will fit into its case just fine. The trick is making sure that the coupler is in the butt (thick portion) of the tube - they aren't meant to be installed on the thinner center section. Once I figure all that out, I miter the rear/seat tube joint portion of the tube (the coupler itself won't clamp well into my mitering fixture, so it's necessary to miter before installing) and cut where I want the coupler. In many cases, I remove a significant portion of the butted section, because the coupler adds quite a bit of length to the tube (about 1 inch) and I need to make sure that I have enough butt at the head tube end.

Next, I clamp the tube in the workstand, cover it with flux, and install the coupler. Here's a picture of the fluxed-up setup. For this end, I don't have to be careful about the orientation of the coupler, because the tube has yet to be mitered.

Next, I braze the coupler in using 56% silver. This isn't the easiest operation, because the coupler is stainless steel, and it has some nasty thin bits that are easy to overheat and cook the flux (meaning that the silver won't flow where it needs to, and the joint won't be a strong as it should). I've done a lot of them, though, so it's not too stressful. This is the same process that is used when building a lugged bike. Here's a picture of the brazed joint.

Next, I braze the other side of the coupler to the short cut-off section of the tube. This time, I have to make sure the points of the lug on the coupler line up with the sides of the tube - I don't like putting points on the top or bottom of the tubes, because I'm a little uncomfortable with the points in the same plane as a lot of the major stresses that the frame will undergo.

Here's a picture of both parts of the coupler brazed into the tube.

Next, I have to get the flux off (it attracts moisture and will end up leading to a rusty tube if it's not cleaned off), so I soak the couplers and tubes in boiling water for 10 minutes or so. I'm not allowed to do this in the house, and I've kicked over the can enough times now that I won't do it in the shop either, so it gets done outside the garage. Yogurt containers are what the pros use, guys.

Finally, I clean off the remnants of the flux with a stainless steel brush. Note that I've done a little bit of polishing of the couplers here so that you can see what's going on, but I won't do a final polishing run on them until the frame is ready to take to the powdercoater. The couplers are stainless, so I like to have them masked so that the polished stainless shows up against the powdercoated tube with a nice defined point. Looks neato, and there's no corrosion concern. Of course, on a mountain bike, the coupler is generally just going to be covered up by a rubber sleeve anyway, but whatever.

Here's the final product, ready to be mitered up and welded into the frame. From here, it's pretty straightforward in terms of frame construction, so the photos and explanations will stop there. I will eventually do an exhaustive "how I build a frame" post or two, but it's not going to be today.

Finally, here are some general thoughts about S&S coupler bikes.

-You will not notice them when riding (unless you can notice the weight, I guess). The couplers are just as stiff as the tube section they replace, and if properly tightened, are undetectable in the ride of the bike.

-They're not cheap. The couplers are $350, and a good hard case is another $300 (I do not recommend the "designer" case that S&S sells). So you'll be $650 in the hole right off the bat. You'll save $50-75 each time you fly, though (usually each way) so you can make that money back in 3 or 4 trips.

-They are a pain to pack. You need practice in packing them, and even with some experience, it will take between 20 minutes (for a road bike) and 45 minutes (for a large 29" mountain bike) to pack the bike. Figure half that time to unpack and reassemble. So they aren't good for extremely short trips - you'll spend more time packing and unpacking than riding if you're just going for a day or two. Sarah and I use ours only for trips that are at least 3 or 4 days long. For shorter trips, we'll just rent bikes or go running instead.

-If not packed *perfectly* they'll get dinged up on the plane because the parts shift around inside. You can pack with lots of foam tubes on the frame and put all your small parts in a clear river-running drybag to keep this from happening, but it will add to the packing and unpacking time. Keep in mind that TSA will often open/rummage through the case, and that they may not be as careful as you are when closing it back up. If scratches or chipped paint upset you, this could be a bad thing.

-Extremely large mountain bikes (over 26" toptube) often will not fit in the 10" (airline kosher) case. I have seldom had my case measured, but if it does happen, you could end up paying the regular bike fee.

-The case+complete large mountain bike weighs about 45 pounds. In most cases, the weight limit for a single item of luggage is 50 pounds, so there's no way to pack lots of other stuff in with the bike without going over.

In summary, S&S couplers rule if you like to travel with your bike, and you have the patience to learn to pack it correctly.

Saturday, February 03, 2007

This one's for the ladies...

You know, for some reason, the ladies never really liked either the original head tube decal (the one with the missing tooth) or the monacle+mustache+gold tooth "classic" decal... so I finally caved, and Chuck D made a new graphic for the ladies. The first batch came out a little bit too big, so the pigtails wrap like halfway around the head tube, but I think that's kinda cool. Looks fast, right?

Subscribe to:

Posts (Atom)